Heat Exchanger Plates

Heat Exchanger Plates

Our heat exchanger plates are designed to deliver efficient thermal performance in plate type heat exchangers used across industrial processes. The engineered corrugation patterns promote controlled turbulence, ensuring improved heat transfer and uniform fluid distribution.

These plates are precisely manufactured for use in plate and frame heat exchangers, offering accurate fitment with PHE gaskets to maintain secure sealing and long-term operational reliability. The design allows easy assembly and disassembly, supporting routine cleaning and maintenance without complexity.

- ■ Low investment costs due to individual design

- ■ Flexibility due to a simple-to-extend system

- ■ Space saving due to a compact design

- ■ Low maintenance costs due to easy maintenance and LocIn changes

Free Flow Plate Heat Exchangers

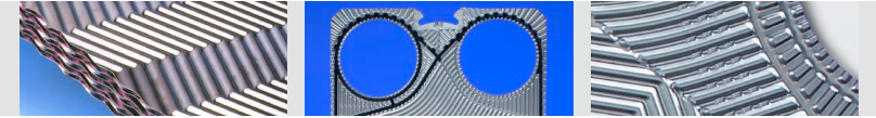

- Cross sections of the Free Flow plates

Free flow plate heat exchangers are developed for applications handling viscous fluids, fibrous media, or fluids containing suspended solids. The open channel plate geometry reduces the risk of clogging while maintaining effective heat transfer within the plate heat exchanger system.

Different cross-section designs of free flow plates enable selection based on process requirements, ensuring stable flow characteristics, controlled pressure drop, and dependable performance in demanding industrial environments.

The new plate heat exchanger generation

- Higher performance, more applications and even less investment: the new versatile SRJNT Series fulfills the requirements of the industry and sets economical standards for future plate heat exchangers.

Features and advantages

OptiWave-design

The optimized corrugation design ensures uniform fluid distribution across the entire plate heat exchanger plate, delivering high heat transfer efficiency while maintaining low pressure drop for stable PHE heat exchanger operation.

PosLoc-fixation

The optimized corrugation design ensures uniform fluid distribution across the entire plate heat exchanger plate, delivering high heat transfer efficiency while maintaining low pressure drop for stable PHE heat exchanger operation.

EcoLoc-gasket system

The glue-free Ecoloc gasket system enables fast, uncomplicated gasket replacement. This design minimizes maintenance time while ensuring secure sealing and consistent performance of PHE gaskets in demanding applications.

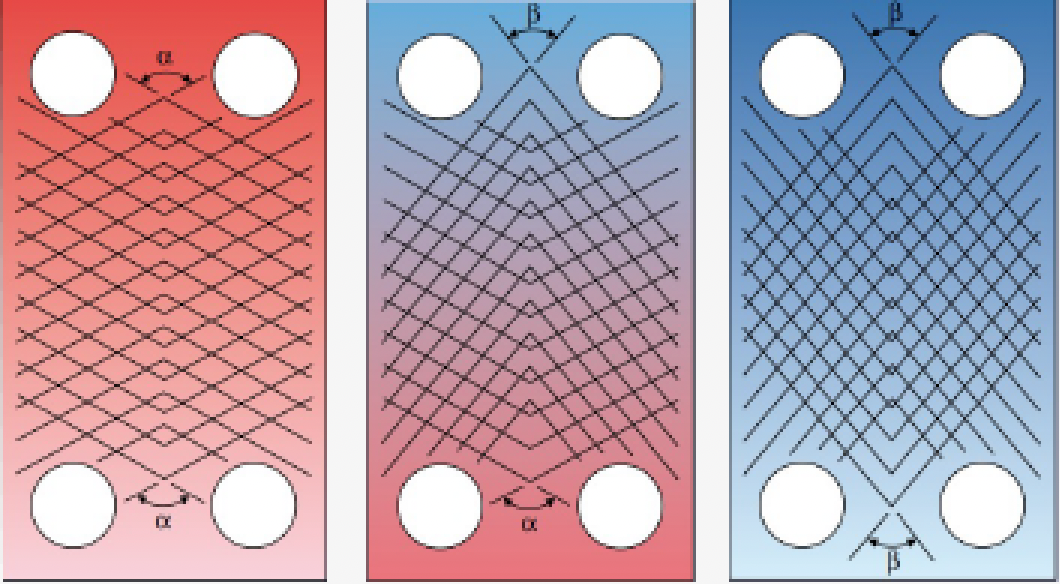

Two types of corrugated plate(L and H)

L: LOW THETA

Designed for applications requiring lower pressure drop and smoother flow characteristics while maintaining effective heat transfer.

H: HIGH THETA

Engineered for higher turbulence and maximum thermal efficiency in plate type heat exchanger duties requiring enhanced heat transfer.

Channel combinations

L + L = L CHANNELS

Suitable for low-viscosity fluids and applications requiring reduced pressure drop.

L + H = M CHANNELS

Balanced performance combining moderate pressure drop with efficient heat transfer.

H + H = H CHANNELS

Optimized for high heat transfer applications where maximum turbulence is required.

- • We choose between L, M and H channels

- • Tailor-make it for the specific duty

- • The Medium Theta cassette is a mixture of High and Low Theta plates. New plate cassettes in alternative material can be inserted when more corrosive cooling water is introduced

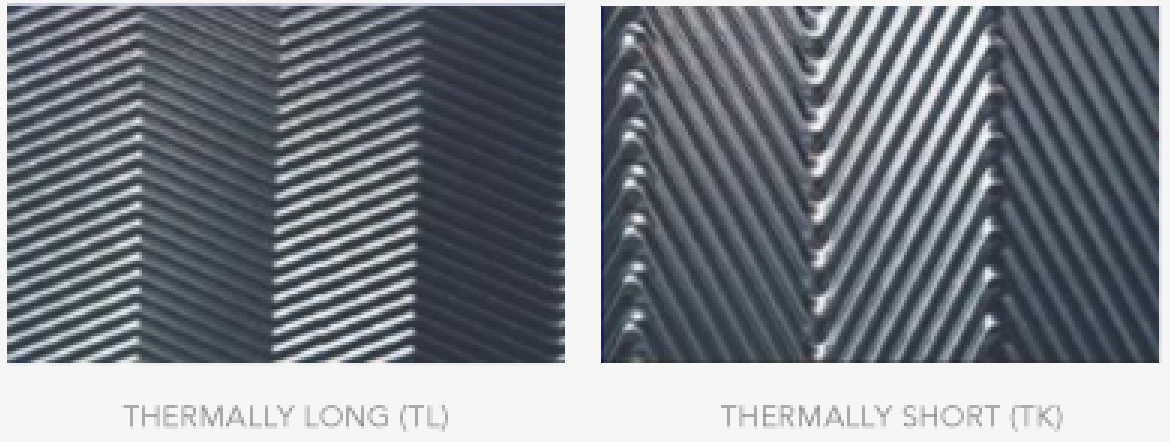

Plate pattern (fishbone)

The fishbone plate pattern is designed to promote uniform fluid distribution and controlled turbulence within the plate and frame heat exchanger. This pattern enhances heat transfer efficiency while maintaining stable flow paths, making it suitable for a wide range of PHE heat exchanger applications.

- flow channels: TL-TL: TL, TK-TK: TK, TL-TK: TM

- Plate pack: TL, TK, TKTLx%, TM, TMTLx%, TKTMx%

- TX plate: almost 180° fishbone, extra long

- Non fishbone: e.g. FreeFlow

Channel grouping:

- The number of channels is defined as “the number of plates - 1”.

- TK - short thermal length

- TM - medium thermal length

- TL- long thermal length

Working Process

The plate and frame heat exchanger operates by directing two fluids through alternate channels formed between corrugated plates. Heat is transferred efficiently across the thin plate surface without mixing the fluids, ensuring controlled thermal exchange and high system efficiency.

This working principle allows PHE heat exchangers to achieve high heat transfer rates within a compact footprint, making them suitable for heating, cooling, condensation, and evaporation processes across industrial applications.