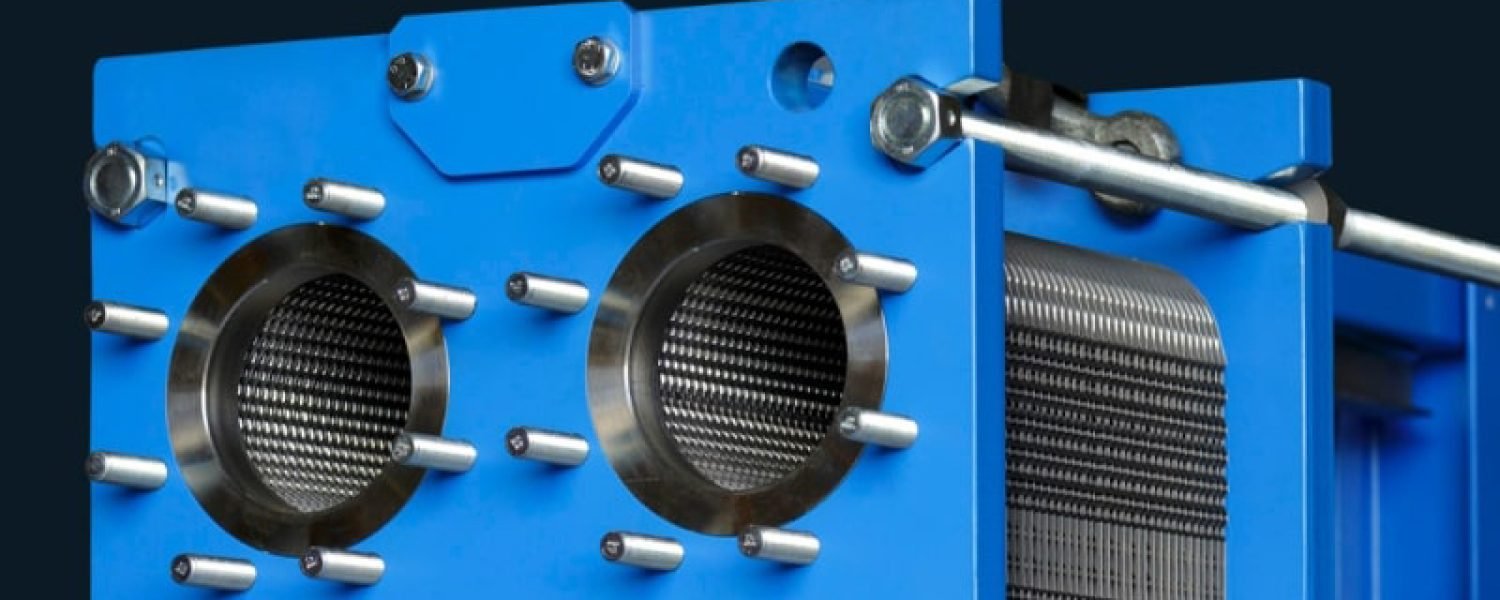

Plate heat exchanger in maintenance steps

In order to ensure the long-term normal operation of the removable plate heat exchanger and reduce the occurrence of accidents, the plate heat exchanger must be maintained. During the inspection process, in addition to checking the operation records of the heat exchanger, we mainly check the appearance to see if there is any abnormality. The key points are as follows:

1. External conditions.

Check the external conditions of the plate heat exchanger in operation, including:

Check the joint part: check whether the welding part of the main body, flange joint, pipe connection part leaks outward or the bolts are loose.

Foundation and support frame inspection: check whether the anchor bolts are loose, whether the cement foundation is cracked or fallen off, and whether the steel support is deformed, damaged or deteriorated.

Inspection of thermal and cold insulation device: check whether the external part of the thermal and cold insulation device is damaged, especially the waterproof layer and support leg covering the external part are easy to be damaged, and pay attention to inspection.

Coating inspection: check the deterioration of the external coating.

Vibration inspection: check whether the main body and connecting pipe have abnormal vibration and sound. In case of any abnormality, find out the cause and take necessary measures.

2. Measure the thickness.

For the heat exchanger running continuously for a long time, it should be worried about its abnormal corrosion. Therefore, the thickness of the shell should be measured from the outside as required, and the corrosion displacement should be calculated. Non-destructive thickness gauges such as ultrasonic shall be used in the measurement process.

3. Internal leakage.

Internal leakage of heat exchanger includes: pipeline corrosion. Thinning and perforation caused by wear; The expansion part is loose due to cracks, corrosion and vibration; Wear caused by contact with baffle. Perforation; Loosen the fastening bolts of the floating head cover. Fracture and deterioration of sealing gasket of these parts. Due to the internal leakage of the heat exchanger and the mixing of the two fluids, it is necessary to disassemble and check the safety immediately, because the staining may occur under normal circumstances. Impurity mixing causes the product to fail to meet the specifications, reduce the quality, and even stop the equipment. Therefore, it is important to find the internal leakage as soon as possible through sampling and analysis of the low pressure fluid outlet of the heat exchanger.

4. Pressure loss.

Find out the amount of fluid pressure loss caused by the products attached inside and outside the pipe.

5. Temperature change.

Measure and investigate the temperature change of each fluid inlet and outlet of the heat exchanger and the process of heat transfer reduction to determine the pollution.

6. Precautions for operation.

The heat exchanger cannot give severe temperature changes. Ordinary heat exchangers take thermal expansion measures based on the operating temperature. Therefore, a sharp temperature change will cause local thermal stress and loosen or damage the pipeline. Therefore, special attention should be paid to temperature rise and fall.

The temperature of cooling water shall not exceed the required level: seawater is used as cooling water on the heat exchanger. If the outlet temperature of cooling water exceeds 50 ℃, it will promote microbial abnormality. On the contrary, the decomposition and adhesion of non-staple food products will sharply lead to pipeline corrosion, perforation and performance degradation, so attention should be paid.

Pay full attention to the abnormal rise of pressure and temperature, fully understand the design conditions of the heat exchanger, and use the instrument to check whether the pressure and temperature rise abnormally.

7. Disassembly inspection and maintenance inspection.

According to the relevant regulations on the failure and performance degradation of the heat exchanger, the operation shall be stopped regularly and the disassembly inspection shall be carried out.